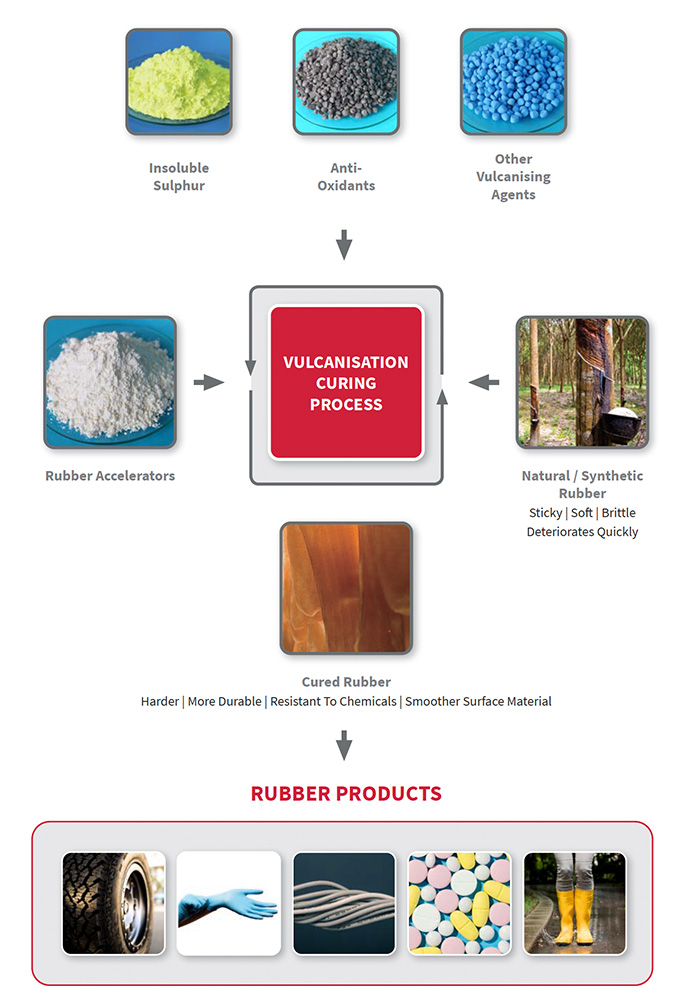

We offer a range of rubber chemical products essential for tyres and other rubber related products such shoes, belts and hoses. The products we produce comprise mainly rubber accelerators, anti-scorching agents, anti-oxidant TMQ & 6PPD and insoluble sulphur. Depending on our customers’ requests, our rubber chemicals can be processed into powdered, granulated or oil-treated forms.

We also provide value-add services to our customers who request such services to mix accelerators with rubber and other additives to form rubber compounds known as master batches based on their required specifications.